Fabrication site construction safety practices project

We have published a set of common minimum safety recommended practices and enabling activities for oil & gas industry construction activities, complemented by a resource library to support implementation.

Report No: 577

This report provides standardized minimum recommended practices for addressing safety risks associated with fatality potential or significant incident hazardous activities common to the fabrication sites.

The recommended practices provide essentials for preventing significant and potential fatality incidents that the governing management system is expected to include.

They are written as statements of ‘must have’ requirements for activities performed at the fabrication sites to meet the expectations of IOGP Members. They can be easily turned into questions and used for pre-start/readiness checklist for construction verification and field verification reviews.

Nine IOGP Members have committed to implementing Report 577. Are you implementing it too? Let us know and we can add your company to the our commitment poster, we’re also keen to hear if you have any feedback.

.

These are pages extracted from IOGP 577 to it make easy to refer to individual recommended practices. Please always consult the full document and check that the extracted pages are from the latest version.

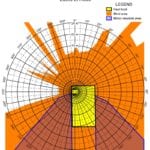

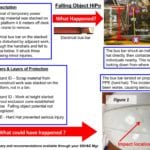

Example of a Dropped Objects Scenario Guide

Example of a Dropped Objects Toolbox Talk

For more on dropped object prevention, including a Drops Calculator, visit DROPS Online

IOGP 577 is consistent with the Korean Shipyard Safety Standardization project, visit their website for more details

Report No: 597

IOGP 597 recommends a set of activities that can help enable a robust safety culture at fabrication sites and is intended for use primarily by fabrication site contractor and subcontractor organizations.

IOGP 597 recommends a set of activities that can help enable a robust safety culture at fabrication sites and is intended for use primarily by fabrication site contractor and subcontractor organizations.

The overall aim is for fabrication sites to achieve the objectives in this guidance through their own management system and to provide a tool for IOGP members to use in site assessments.

The enabling activities described in IOGP 597 have been selected based on industry practices and are not intended to be comprehensive. Fabrication site HSE management systems may already address some or all of the activities in this report, or may include additional activities not covered, therefore the enabling activities can be applied selectively based on need. The enabling activities are not detailed procedures but rather provide guidance, which is intended to help evolve the safety culture and safety performance of a site.

These are pages extracted from IOGP 597 to it make easy to refer to individual recommended practices. Please always consult the full document and check that the extracted pages are from the latest version.