Process Safety Fundamentals

The IOGP Process Safety Fundamentals (PSFs) have been developed to support companies as they seek to reduce, and ultimately eliminate, fatal and high severity process safety events.

Designed to support those working in front-line operations, maintenance, and on wells teams, the PSF are informed by data and designed to draw attention to situations that are most likely to lead to process safety event fatalities.

“NOPSEMA expects the oil and gas industry to take all practicable steps to eliminate fatalities and Major Accident Events across all their activities. We believe that adoption of the IOGP Process Safety Fundamentals will contribute to further reductions in Process Safety incidents and the achievement of that goal.”

Derrick O’Keeffe, Head of Division, Safety and Integrity, NOPSEMA

FAQs - Frequently asked questions about process safety fundamentals

What are the Process Safety Fundamentals?

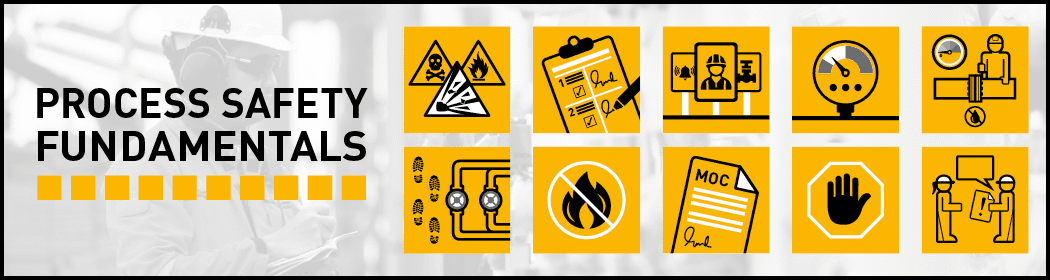

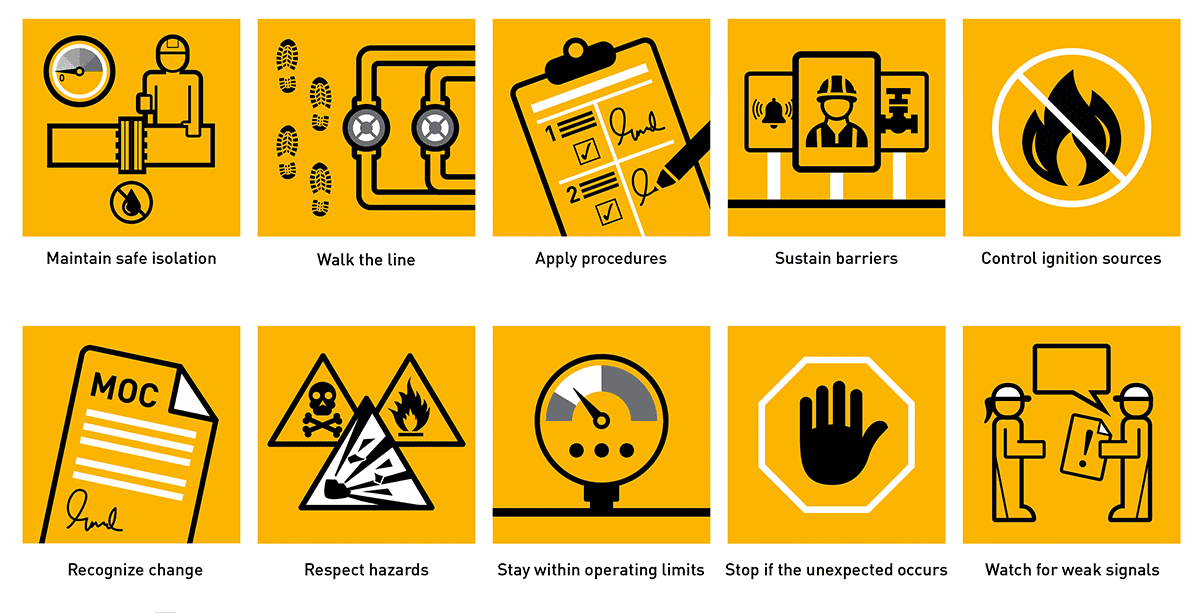

The Process Safety Fundamentals (PSFs) are a set of basic principles for front-line workers, supervisors, and managers that emphasise existing good practices to prevent fatalities from Process Safety Events. Preventing Process Safety Events is important because they can escalate into catastrophic events.

Why use the Process Safety Fundamentals?

The Process Safety Fundamentals are different than and complementary to programs such as IOGP’s Life-Saving Rules, which focus on personal safety. The Process Safety Fundamentals program aims to enable front-line workers to raise concerns openly and transparently. It is expected that it may not always be possible to follow a particular Process Safety Fundamental, but with the Process Safety Fundamentals the front-line is empowered to raise issues and dilemmas, helping to ensure effective Process Safety Management, including potential engineering modifications to address the issues raised.

Is implementation of the Process Safety Fundamentals mandatory for IOGP Members?

No, implementation of the Process Safety Fundamentals is not mandatory for IOGP Members.

Annual data reported by IOGP Members shows an average of 5 fatal Process Safety Events per year. IOGP developed a set of Process Safety Fundamentals tailored to eliminate such events and help the industry to achieve zero fatalities. IOGP encourages Members and the wider industry to implement the Process Safety Fundamentals.

Implementatation resources

Download these resources to assist your implementation efforts

Supporting your front line

It is important that front-line workers are given the flexibility to use the PSFs as a supportive tool to help improve process safety performance.

There will be situations when trying to align with a PSF may prove difficult – this is expected.

The PSF should be launched in a way that enables and empowers the frontline workers to openly voice and report these dilemmas without fear of criticism or reprisal. Only by bringing these issues into the open can the implementing company learn of them and determine how to address them. PSFs are not intended to be seen as ‘another set of rules’, and it is strongly advised that they are not associated with disciplinary measures for non-conformance.

Video Showcase

Videos produced by IOGP Members as they implement PSF in their organization

These materials are freely shared by our IOGP-Members and Non-Members, if these have benefited your organization and you also have materials that you would like to share for the wider benefit of others, please contact Dr. Ismaeel Husain, IOGP Senior Health and Safety Manager at iah@iogp.org

Other videos and resources

The following resources have been published by other organisations and do not directly relate to the IOGP PSF, but they are excellent at explaining concepts, processes or lessons learned from events that are integral to the IOGP PSF.

- Always Safe

- Energy Institute Reflective learning (videos)

- Kaltura

- Step Change in Safety:

- CCPS Beacon

- US Chemical Safety Board videos

- Preliminary Animation of Philadelphia Energy Solutions Refinery Fire and Explosions

- Winterization Safety Message

- Fire in Baton Rouge

- Explosion and Fire at Refinery in Wisconsin

- Blowout in Oklahoma

- Anatomy of a disaster

- Fire from ice

- CSB Safety Bulletin Says “Managing Change” Is Essential to Safe Chemical Process Operations”.

- Safer Together videos and other tools in particular We all have a part to play

- UK Health and Safety Executive The safe isolation of plant and equipment

Where did the Process Safety Fundamentals come from?

Data reported by IOGP Members over a period of ten years (2007-2017) shows that 128 people lost their lives in 56 Process Safety Events (PSEs).

Analysis of the process safety related fatal incidents was conducted by the team with the aim of determining what types of potential PSFs were a factor in the incidents and how, if they had been implemented effectively, they might have prevented or mitigated the fatal consequences of these incidents.

The analysis considered a broad range of potential PSFs influenced by both the information on the fatal incidents provided by IOGP members and members experience. Each fatal PSE was reviewed against the list of potential PSFs and linked to one or more of the PSFs. By determining which of the PSFs could be linked to either the highest number of fatal incidents or number of fatalities allowed a shortlist of PSFs to be identified which eventually became the 10 IOGP PSFs.

For more on the data analysis – see Process Safety Fundamentals.